In the images above, you can see that I have applied liquid white enamel to the areas of my piece that have been stamped. After allowing the enamel to dry, I use the edge of a credit card or a piece of box board to scrape away the majority of the enamel. You want to make sure you leave the enamel in the depressions.

Clean up any residue around your stamped design with a damp paint brush. It shouldn't be wet, or you'll end up with a mess.

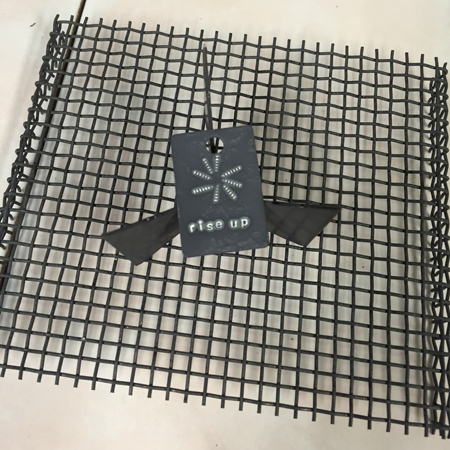

Next, fire your piece in the kiln or with a torch from the underside. The exposed copper will oxidize to a dark black. You can throw it in the pickle pot once it cools, to clean off the oxidation. Alternatively, you can sand it with some fine grade wet-dry sandpaper under running water.

After the exposed copper is clean, you can add a patina or leave it as is. I like the rustic look of the patina, so I use a little liver of sulphur to achieve the aged look. Apply the liver of sulphur as you would normally and neutralize in a baking soda and water solution. Dry completely and buff with a pro-polish pad or use some fine grade wet-dry sandpaper, as I did, to remove the patina from select areas.

Voila! There you have an easy champleve in less time than it took you to cut out a design and solder.

Now, if you want to, as I mentioned earlier, you can give your design more color and accents with some transparent enamel. It requires counter enamel to do that. Here is an example of what you can do. I have also created a design in the center of this piece using the sgraffito technique.